The three letters PET stand for Polyethylene Terephthalte, a 100% recyclable material used in plastic bottles. After PVC in the early 1990s, PET quickly became the standard material for bottling. Driven by a logic of circular economy and committed to reducing its impact on the environment as much as possible while meeting the expectations of its consumers, our Florihana brand currently uses 100% recyclable PET for its bottles of natural and organic Hydrosols, Carrier Oils and Macerated Oils, with very low recycling energy costs.

Through a virtuous and sustainable ecological approach, opting for 100% recyclable PET bottling allows us firstly to revalue our packaging either in many other areas (such as textiles) or to create new containers, unlike glass in particular, which can only be converted into certain forms of glass. Today, PET plastic is the most recycled plastic in the world. In France, more than one bottle out of two is recycled then reused.

Less polluting, the manufacture of PET bottles is also more economical in terms of oil consumption. Very light and continuously optimized, already around 30% lighter than 15 years ago*, this economical material requires much less energy for transport than glass in particular, which is heavier. PET is practically unbreakable and has a very high strength-to-weight ratio, unlike glass that is more fragile. The risk of damage and breakage is considerably reduced, thus lowering the risk of multiplying by two to four the environmental footprint of the product. In particular, a truck can carry twice as much PET plastic as it is lighter and use every available free space without overloading the vehicle, thus greatly diminishing the carbon footprint.

Regarding our Hydrosols, Carrier Oils and Macerated Oils, all are quite heavy products, especially when ordered in quantities of 500ml or 1l. To remain competitive while meeting our consumers' expectations for an express delivery, which is usually expensive, our orders travel mostly by air. By using this means of transportation, we take into consideration the fact that glass is very fragile and much more likely to break, especially when travelling long distances. The risk of leakage or breakage would increase the amount of waste and the size of our boxes, which is crucial for transport companies that charge shipping costs according to the packaging's volume and weight. In this case, glass may also significantly increase the weight of the package and directly impact the amount of fuel consumed during transportation, as well as the carbon footprint. Adding 2kg per order for every 1000 orders would result in more than 2 tons of products to be transported from A to B, requiring a lot of fossil energy and polluting even more.

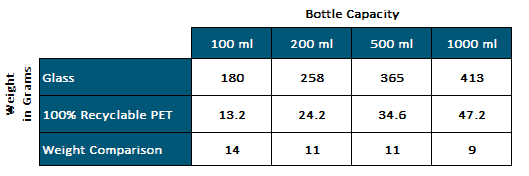

Below is a table comparing the weight of glass bottles* and that of 100% recyclable PET bottles, demonstrating the direct impact on the carbon footprint depending on the material used:

*Average estimates

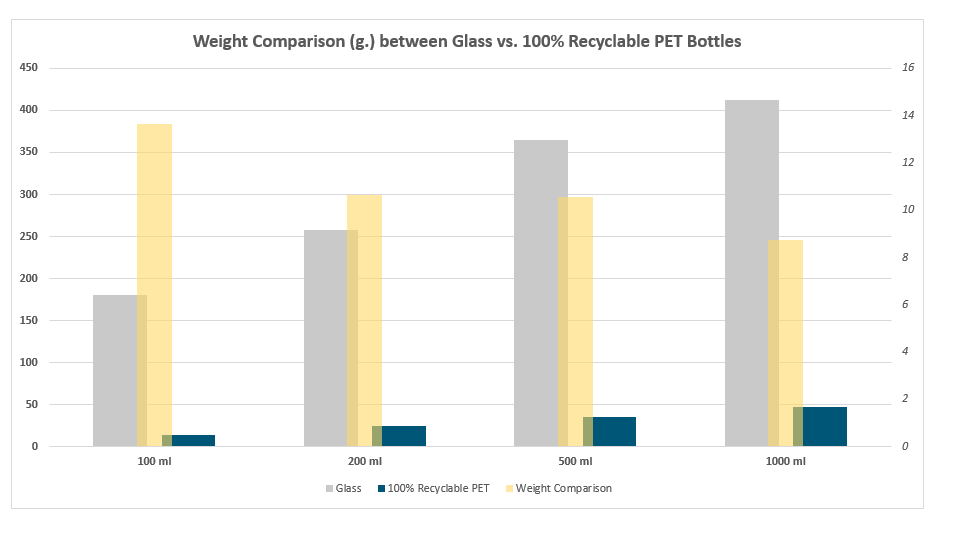

According to this comparison, a 100ml 100% recyclable PET bottle is 14 times lighter than a glass bottle with the same capacity, and a 1l 100% recyclable PET bottle is 9 times lighter than a glass bottle of the same content. These weight comparisons (in grams) are also illustrated in the following graph, with the glass bottles in grey, the 100% recyclable PET bottles in blue and their respective weight differences in yellow. Overall, the weight of the 100% recyclable PET bottles we currently use is much lower than that of glass bottles, regardless of their capacity. In light of this, we chose to use 100% recyclable PET bottles for the time being so as to reduce as much as possible our carbon footprint in the context of our business activities.

In addition, our PET bottles are colored blue to protect the product inside. Slightly transparent, our consumers are able to quickly visualize the latter by looking through the bottle. PET preserves our Hydrosols, Carrier Oils and Macerated Oils from external contamination due to its high chemical resistance to organic substances and water. Certified Food Grade according to the European Regulation 2023/2006, deemed safe and widely accepted by the current sanitary authorities, it is risk-free for our customers, from bottling to final use.

In addition, our PET bottles are colored blue to protect the product inside. Slightly transparent, our consumers are able to quickly visualize the latter by looking through the bottle. PET preserves our Hydrosols, Carrier Oils and Macerated Oils from external contamination due to its high chemical resistance to organic substances and water. Certified Food Grade according to the European Regulation 2023/2006, deemed safe and widely accepted by the current sanitary authorities, it is risk-free for our customers, from bottling to final use.

Being well aware that 100% recyclable PET is not a perfect material but a much more ecological and economical compromise for the time being, our company is actively looking for new sustainable alternatives and very soon plans to inject its bottles on site using biodegradable containers, particularly made from algae. Until then, we would like to encourage all our consumers to recycle and reuse our 100% recyclable PET bottles as they should be. To maintain the virtuous circle of sustainability, everyone should play their part by properly recycling the various materials used, including recyclable PET, in order to reduce waste volumes, resource consumption and environmental pollution over the short and long term.

To learn more about our Florihana brand and our sustainable commitments, we invite you to explore our website or contact us directly using our online form here attached.

*Source (in French): https://www.encyclo-ecolo.com/PET